Past Issues

A Review of Exploitation Techniques of Barite Deposits of Nasarawa State, Nigeria

Abdulraman Sikiru Ottan1*, Itohan Otoijamun2, Adedoyin Adeonipekun Dele3, Azikwe Peter Onwualu4

1Materials Science and Engineering Department, Kwara State University, Nigeria

2National Agency for Science and Engineering Infrastructure (NASENI), Nigeria

3Department of Geology and Mineral Sciences, University of Ilorin, Nigeria

4Materials Science and Engineering Department, African University of Science and Technology, Nigeria

*Corresponding author: Abdulraman Sikiru Ottan, Materials Science and Engineering Department, Kwara State University, Malete, Ilorin, Nigeria, Tel: +2348033979980 E-mail: [email protected]

Received: April 23, 2022

Published: October 10, 2022

Citation: Abdulraman SO, et al. (2022). A Review of Exploitation Techniques of Barite Deposits of Nasarawa State, Nigeria. Material Science. 4(2):14.

Copyright: Abdulraman SO, et al. © (2022).

ABSTRACT

The geometry and types of barite deposit affect mining economics and processing complexity. Nasarawa state barite deposits are cavity filling types with inherent complex geometry that is beyond the comprehension of the workforce (artisanal miners) involved in the production value chain. This study reviewed the barite production from Nasarawa State; and the current exploitation techniques were evaluated through monitoring of field operations; questionnaire; and personal interview. The questionnaire addressed critical issues relating to exploitation of barite which include management and control of barite mining and processing operations; level of technical skill; mechanization; mine safety and hygiene; mine productivity; host community relation; and mineral economics related matters such as monetization of mined products. Twelve (12) barite mining locations were visited, and eighteen (18) barite veins were studied. The veins run almost parallel to each other and averagely 80cm thick, 1m wide, and overlaid by about 20m overburden of varying materials (laterite, and sandstone, etc.). Consensus submission of the respondents and interviewees is that lack of technical skill and support hinders efficient operations at the mine sites. Barite mining pits are abandoned prematurely and inexhaustibly resulting from poor exploitation techniques due to lack of adequate profiling of the deposits that impacts negatively on sustainable development of Nasarawa state barite deposits. It becomes imperative therefore to delineate the deposits and adopt appropriate exploitation technique while enhancing the technical skills of the workforce through human capacity development.

Keywords: Nasarawa, Barite, Exploitation, ASM, Sustainable Workforce, Vein, Mechanization

INTRODUCTION

Nigeria is moderately endowed with varieties of solid mineral resources located across the 36 states of the Federation including the Federal Capital Territory. These minerals include metallic minerals (iron ores, cassiterite, lead-zinc ores, gold, tantalite, columbite, etc.); industrial minerals (limestone, clay, feldspar, barite, kaolin, and diatomite); energy minerals (coal, uranium, and bitumen); and construction materials (dimension stones limestone, and gravels). The exploitation of mineral resources has assumed prime importance in several developing countries, Nigeria inclusive and to harness these resources, they have to pass through the stages of exploration, mining, and processing or beneficiation.

Nasarawa state lies within the north-central zones of Nigeria and known for huge production of mineral resources in all the 13 local government areas of the state. Some of these minerals include Cassiterite, Granite, Barite, Salt, Lime, Zinc, Lead, Clay, Silica, Aquamarine, Sapphire, Amethyst, etc. In 2016, Nasarawa State produced a total of 73,360,157 tons of solid minerals [1]. Largely, most mineral resources of Nasarawa state are worked by artisanal miners.

Fundamentally, Artisanal and Small-scale Mining (ASM) is generally pursued as a route out of poverty or as an activity to complement insufficient income, especially in communities where alternative employment is hard to come by. ASM is a very diverse sector, its main challenges vary from region to region and often from site to site. There is a perception that ASM is a “get-rich-quick” activity and has misinformed legislation and led to inappropriate government policies regarding the sector. In 2016, about 500,000 personnel are directly involved in ASM of gold with an estimated 2,500,000 dependents [2]. The value chain of the operation is highly labour intensive with resultant poor productivity. Despite its low productivity, ASM is an important source of minerals and metals. It accounts for about 20% of the global gold supply, 80% of sapphire supply, and 20% of diamond supply. ASM is also a major producer of tantalum and niobium minerals for manufacturing capacitors in the electronic industry (i.e., laptops and cell phones). Reports show that 26% of global tantalum production and 25% of tin come from ASM [3].

Over time, the Nigerian economy is largely premised on oil revenue and the exploitation of oil relies on an appreciable supply of barite ore as a key constituent of drilling mud used to stabilize the oil well; prevent blow-out; remove cuttings; lubricate and cool the drilling stem during oil well drilling. Hence, the criticality of a sustainable production of barite.

Several kinds of literature (published and unpublished) e.g. [4,5,6,7] exist regarding barite mineralization within Nasarawa state and records of production by private operators and Nigerian Mining Corporation (NMC) while in operation. Today, barite mining is largely dominated by artisanal miners whose operations are being carried out using crude implements (such as hammers, chisels, shovels, head pan, etc.) and without any formal exploitation technique that can guarantee the sustainable development of the barite ore resources. This paper therefore reviews the barite deposit of Nasarawa state and their exploitation techniques.

Nasarawa state lies between latitude 7° 45′ and 9° 26′ North and longitude 6° 55′ and 9o 42′ East. The state is accessible by a good network of roads through Benue State to the South, and Kogi State to the West. The Federal Capital Territory (FCT), Abuja is to the North-west, Kaduna and Plateau States to the North-east, and Taraba State to the South-east. However, the barite mineralization zones of the state lie within Latitude 8° 01′ N – 8° 29′ N and Longitude 9°03′ E – 9° 23′ E. Generally, barite ore deposits can be classified into bedded-sedimentary; bedded-volcanic; vein; and residual types. Nasarawa state barite ore deposits are largely of vein (cavity filling) type with few residual deposits occurring at shallow depths. The barite deposits have varying host rocks mainly silicates (quartzites and clay). This study aims to review the exploitation techniques of barite deposits in Nasarawa state. Objectives of the study are to: i. study the geology of the barite deposits; ii. assess the current exploitation techniques; iii. evaluate operational challenges in the current techniques; and iv. determine the possibility of mechanization of the operations.

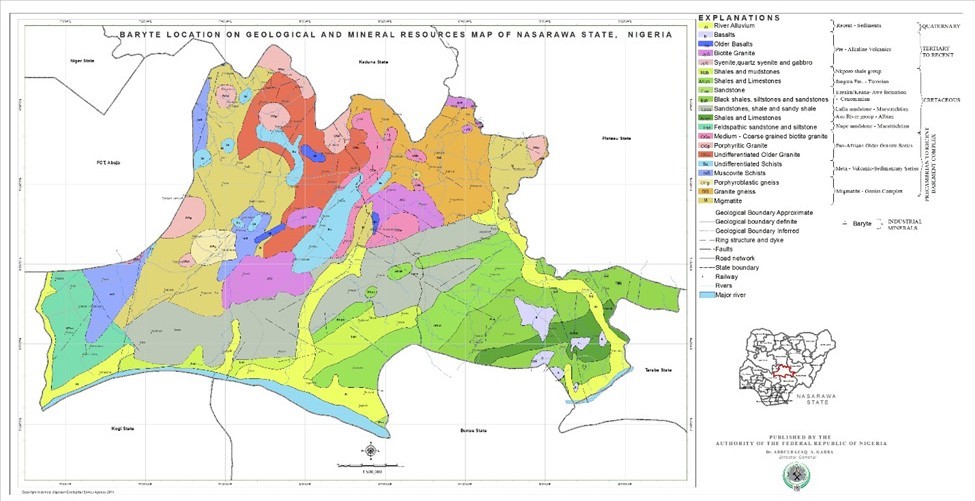

Figure 1: Geological and Mineral Resources Map of Nasarawa State, Nigeria [8].

MATERIALS AND METHODS

The lithology of Nasarawa State barite deposits has been investigated by studying rocks exposure from mining pits. Current exploitation and processing techniques of barite ores at the sites were assessed by monitoring the site operations; and the opinions of stakeholders at the various sites regarding operating techniques and associated challenges were reviewed through questionnaires and structured interviews. The questionnaire was structured to address critical issues relating to exploitation of barite which include management and control of mining and processing operations; level of technical skill; level of mechanization; mine safety and hygiene; measure of productivity; mine host community relation; and mineral economics related matters such as ease of sales of mined barite, selling price, and remuneration of workforce.

RESULTS AND DISCUSSION

Profile of Some Barite Deposits in Nasarawa State Nasarawa barite deposits occur around Azara, Wuse, Kumar, Aloshi, and Keana areas. Coordinates of barite mining locations in Nasarawa state visited were captured using ‘Garmin’ GPS machine and reported in Table 1. The lithological description of some Nasarawa barite deposits is given in the following section.

Table 1: The coordinates of some barite mining locations.

|

S/No. |

Name of Location |

GPS Coordinates |

|

1 |

Vein 17 - Azara |

N 08° 22′ 27.6′′ E 009° 17′ 30.8′′ |

|

2 |

Vein 1 - Azara |

N 08° 20′ 39.8′′ E 009° 17′ 22.5′′ |

|

3 |

Sofo rami – Azara |

N 08° 18′ 36.7′′ E 009° 15′ 50.6′′ |

|

4 |

Sauni Serki - Azara |

N 08° 18′ 08.2′′ E 009° 14′ 53.33′′ |

|

5 |

Kumar Village |

N 08° 19′ 53.6′′ E 009° 27′ 26.7′′ |

|

6 |

Dogon daji – Wuse |

N 08° 20′ 47.0′′ E 009° 22′ 27′′ |

|

7 |

Ribi Site - Wuse |

N 08° 24′ 58.8′′ E 009° 08′ 03.0′′ |

|

8 |

Gidan bera - Keana |

N 08° 02′ 09′′ E 008° 56′ 26.2′′ |

|

9 |

Aloshi |

N 08° 14′ 48. 6′′ E 008° 48′ 17.0′′ |

|

10 |

Kuduku 1 |

N 08° 09′ 07.3′′ E 008° 44′ 29.0′′ |

|

11 |

Kuduku 2 |

N 08° 11′ 07.8′′ E 008° 45′ 20.7′′ |

|

12 |

Kuduku 3 |

N 08° 11′ 52.2′′ E 008° 45′ 52.2′′ |

Azara barite deposit is of cavity filling type (Veins). The vein is 0.1 – 1.2m thick, 0.8 – 1.6m wide and stretched through the entire length of paddock opened up for barite mining, which is about 900m. Azara barite mineralization is composed of 18 veins running almost parallel to each other, sometimes with split veins occurring at a shallow depth of 4m below the ground level. The veins were named by N.M.C when operational. Main veins are overlaid by an overburden of 15 – 20m thick consisting of Topsoil, Laterite, Shale and Sandstone in some places. The barite ores occur with impurities such as Hematite, Sphalerite, and Siderite. Vein 17 in Azara occurs at a depth of about 30m, its thickness is about 5m, width is about 2m and nearly a kilometer long. Vein 18 is a split-vein with a residual deposit of barite occurring at a shallow depth of about 4m, its width ranges between 40cm – 65cm. Core drilling exercise commissioned by NGSA is ongoing on the vein for adequate probing of the property. The spacing between veins 17 and 18 is about 150m. Vein 1 was partly worked by Nigeria Mining Corporation (NMC). The vein dimensions are similar to those of veins 17 and 18. Its overburden is largely dominated by white clay whose average thickness is about 6.5m. Sofo rami is another vein within the Azara mineralization zone. Depth, width, and thickness of the vein are 20m, 0.8 – 1.15m, and 2m respectively. Crystalline barite ore occurs as a residual deposit at a shallow depth of about 4m; most of the barite ores in this location have Clay, Hematite, and Sphalerite as impurities. Sauri- Serki is another barite location in Azara, the barite vein occurs 30m below the ground surface, about 2m wide, 7.5m thick, and stretched a distance of about 1km. It has similar host rocks as “Sofo- rami” and the ore occur with quartzite, hematite, and sphalerite.

Kumar deposit is of residual type at about 5.3m below the ground level; the main vein occurs at a depth of about 12m; though, narrowly formed, about 0.65m wide and 1.3m thick.

In Wuse (Dogon-Daji), the vein is 0.40m – 1.8m thick, about 1.5m wide, and occurs at a depth of about 15m below the ground level and covers a lateral distance of about 3km. Residual deposit of barite also occurs at a shallow depth of about 5m below the surface.

Ribi site has a vein of about 1.5m width, 2m thickness, 900m long occurring at a depth of 15m depth and overlaid by clay deposit. Semi-mechanized operation is going on at the site by an operator (Allah de Nig. Ltd).

In Kaena (Gidan-bera) site, there is evidence of semimechanized operation with organized stacking of overburden around the paddocks. The overburden materials are composed of Clay and Quartzite. The barite material is crystalline, but the pits are filled with water, which is evidence of premature closure of the site possibly caused by poor exploitation technique.

Aloshi site has veins occurring at a depth of 10 – 15m, 0.60m wide, and about 700m long. The host rock is mainly Quartzite and Orthoclase feldspar (Silicates) outcrop, averagely 5m above ground level. The host rock is very hard which makes exploitation of barite more difficult and challenging for artisanal miners.

Kuduku site has similar topography and lithology as Aloshi area, except that the host rock is overlaid by about 2.5m thick Laterite and the barite ore occur together with Galena. The occurrence of barite with Galena has a potential threat to the mine environment as a result of possible Pb dissolution, especially the water sources near the mining sites.

Generally, Nasarawa barite deposits are of cavity filling type (Veins). There are about 18 veins running either almost parallel or different orientations to each other, sometimes with split veins occurring at shallow depths of about 4m below the ground level. The veins are averagely 0.1 – 1.2m thick, 0.8 – 1.6m wide, and stretched through the entire lengths of paddocks opened up for barite mining, which are in excess of 20 kilometers altogether. Main veins are overlaid by an overburden of 15 – 20m thickness consisting of Topsoil, Laterite, Shale, and Sandstone in some places. The barite ores occur with impurities such as Hematite, Sphalerite, and Siderite.

Assessment Report of the Current Exploitation Techniques of Barite in Nasarawa State

A number of open-cast workings assessed show clear evidence of extensive Artisanal and Small-scale Mining (ASM) activities for barite in Nasarawa State. Virtually all the barite ores occur as vein deposits and are exploited archaically. It is quite obvious that the mine developments are directed intuitively. Miners follow the visible mineralization vertically and laterally without having a clear idea of the location and grades of the mineral reserves. The deep part of the barite mineralization is abandoned as soon as the extraction becomes delicate and expensive.

Extraction is done using crude implements such as diggers, shovels, and buckets (Figure 2). When the pits become dip, extracted materials are transferred to the pit collar (using draw buckets with long ropes) for onward transfer to the washing location. Women and children are engaged (by site owners or vendors) to transfer materials to washing points and for processing (i.e., washing, sorting, and drying) and stacking of mined barite.

At the collection point, boxes with dimensions 0.9m by 0.9m by 0.6m are used to evaluate the barite productions (Figures 3 and 4) for operational economics. A full box is estimated as one ton of barite. This exploitation method poses a challenge to the sustainable development of Nasarawa state barite deposits. Despite available Global best processing techniques for barite ores, manual and crude method of washing is the norm in the state. This practice decreases the economic value of the ore and increases the transport cost to the end-users. Barite produced are transported out of production site in trucks to millers who then further process, mill, and package them in bags for use in oil drilling. Nasarawa state barite has an average specific gravity of 4.2g/cm3 which is within the API standard as a constituent for use in drilling mud. Large percentage of barite ores supplied to Nigerian oil industry is sourced from Nasarawa state.

Also, the rocks hosting the barite ore have sufficient water storage within the rock mass, possibly close to the region’s water table or close to a sub-lake that keep waterflow running for a significant time, together with a connecting network of fractures, daylighting in the pit, each of sufficient hydraulic conductivity to influence waterflow into the mining pit. These hydrological challenges cause delays; collapse of pit walls and danger to artisanal miners resulting in poor productivity. However, huge volumes of adhering materials with the barite ores either as overburden and/or host rocks especially the clay materials are compulsorily excavated to access the mineral of interest (barite) while maintaining safe slope angles within the mining pits. Indiscriminate stacking of these materials has an environmental impact on the mining operation. Hence, the need to characterize all likely mineable materials (both host rocks and barite ores) for sustainable mine development, enhanced mineral resource base, wider industrial applications, and higher project viability.

Mechanization of Barite Mining Operation in Nasarawa State, Nigeria In consideration of the profile of the barite deposit in the studied locations (especially the depth and dimension of barite ores within the formation), some unit operations of the barite production can be mechanized to enhance productivity. The formations can be drilled, blasted and the muck excavated, and transported to a processing facility to be stationed near the mining sites in order to bring the ore to the technical requirements of the customers (i.e., drilling mud millers). Processing methods for recovery of barite largely depend on the type of ore and gangue composition. Also, it depends on the liberation size of the barite. When the liberation size is very fine, floatation is the preferred method. Barite ore is concentrated physically using gravity separation and/or magnetic separation method if the ore contains ferrous impurities.

Mechanization of Barite Mining Operation in Nasarawa State, Nigeria In consideration of the profile of the barite deposit in the studied locations (especially the depth and dimension of barite ores within the formation), some unit operations of the barite production can be mechanized to enhance productivity. The formations can be drilled, blasted and the muck excavated, and transported to a processing facility to be stationed near the mining sites in order to bring the ore to the technical requirements of the customers (i.e., drilling mud millers). Processing methods for recovery of barite largely depend on the type of ore and gangue composition. Also, it depends on the liberation size of the barite. When the liberation size is very fine, floatation is the preferred method. Barite ore is concentrated physically using gravity separation and/or magnetic separation method if the ore contains ferrous impurities.

Figure 2: Artisanal mining of barite in Azara, Nasarawa state (A- Potential pit wall failure supported by wooden props, B, C and D shows artisanal miners working at deeper levels) [7]

Figure 3: Stacking of mined barite

Figure 4: Evaluation of Barite [9] Production [9]

CONCLUSION

The potential of Nasarawa State’s barite resource is not in doubt except for the operational flaws and environmental challenges associated with the current exploitation techniques. Most of the problems facing barite productions in Nasarawa State stem from lack of proper evaluation of their design integrity, poor infrastructure, and lack of skilful workforce. Investigation into poor performances at the mining sites revealed problems about the true profile of the barite deposit and appropriate exploitation and processing techniques. There is therefore none of the barite mining pits producing optimally; a large volume of waste rocks is compulsorily excavated to access barite while maintaining safe slope angles within the mining pits. Indiscriminate stacking of these materials impacts negatively on the barite mining. It is imperative therefore, to characterize all likely mineable materials (both waste rocks and barite ores) for sustainable mine development, enhanced mineral resource base, wider industrial applications, and higher project viability.

RECOMMENDATIONS

Considering the numerous challenges associated with the current practices of the value chain, the following recommendations are given: i There is a need to delineate the barite resources using any or combination of exploration techniques such as Gravity method, Core drilling, and Resistivity method, etc. ii Mining pits should be properly developed with appropriate pit geometry design to enhance full mechanization that will guarantee high productivity iii Mining operation must be guided by knowledge; hence, the miners should be trained to adopt an appropriate mining method for sustainable barite ore development.

ACKNOWLEDGEMENT

We sincerely acknowledge the cooperation of the artisanal miners for their kind acceptance and openness in providing their views based on field experiences regarding the exploitation of barite deposits of Nasarawa State, Nigeria.

REFERENCES

1. State’s Disaggregated Mining and Quarrying Data, 2016. www.nigerianstat.gov.ng

2. Hilson G. (2016). Farming, small-scale mining and rural livelihoods in sub-Saharan Africa: a critical overview. Extractive Industries and Society, 3(2): 547–563.

3. Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development (IGF). (2017). Global Trends in Artisanal and Small-Scale Mining (ASM): A review of key numbers and issues. Winnipeg: IISD, 91.

4. Mgbemere HE; Obidiegwu, EO, Obareki E. (2018). Beneficiation of Azara Barite Ore Using a Combination of Jigging, Froth Flotation and Leaching. Nigerian Journal of Technology. 37(4): 957- 962.

5. Tanko IY, Adam M, Shettima B. (2015). Petrology and Geochemistry of Barite Mineralisation Around Azara, North Central Nigeria, International Journal of Science & Technology Research. 4(5): 44- 49.

6. Ishaya S, Alhassan MM, and Ndako Nma (2018). Effects of Baryte Mining on Water Quality in Azara- Awe Local Government Area of Nasarawa State, Nigeria, Annals of Ecology and Environmental Science, 2(1): 1- 9.

7. Onwualu AP, Igbokoyi A, Abdulraman SO, Ogbe D, I.tohan O, et al. (Unpublished). (2019). Field Trip Report on Barite Mineralization within Nasarawa State, p.23.

8. Nigeria Geological Survey Agency (NGSA) (2019). Baryte Location on Geological and Mineral Resources Map of Nasarawa State, Nigeria, p.1.

9. Itohan O, Kigozi M, Abdulraman SO, Adetunji AR and Onwualu AP. (2021). Fostering the Sustainability of Artisanal and Small-scale Mining (ASM) of Barite in Nasarawa State, Nigeria. MDPI, Besel, Switzerland. p.23.

Abstract

Abstract  PDF

PDF