Past Issues

Vertical and Horizontal Cell Structural Appraisal of a 9-Year Cedrela odorata L. (Miliaceae) for Pulp and Paper Making

Peter Kessels Dadzie1*, Martin Amoah2, Paul Benedict Inkum1, Ernest Boampong1, Victor Owusu Ansah Jr3

1Interior Design and Materials Technology Department, Kumasi Technical University, Box 854, Kumasi, Ghana

2Faculty of Technical Education, University of Education Winneba, Kumasi Campus, Kumasi, Ghana

3Centre for Research and Development for Technology Incubation (CRDTI), Kumasi Technical University, Box 854, Kumasi, Ghana

*Corresponding Author: Peter Kessels Dadzie, Interior Design and Materials Technology Department, Kumasi Technical University, Box 854, Kumasi, Ghana, Tel: +233-243351806; E-mail: [email protected]; [email protected]

Received Date: December 17, 2020

Published Date: March 05, 2021

ABSTRACT

Paper is a material of importance in human life and produced from wood. However, is not all wood that have the qualities to be used for paper production. This study assesses the suitability of a 9-year old Cedrelaodorata wood in both vertical (bottom to top) and horizontal (sapwood to heartwood) directions for pulp and paper making. Specifically, we evaluated the variations in fibre dimensions and other derived technical requirements needed for wood to be used for paper production. Franklin’s maceration process was adopted for the study. Collected data was subjected to statistical analysis using IBM Statistical Package for Social Sciences (SPSS) version 17.00. Mean fibre length was found to be short (i.e., ranged from 0.822 ±0.142 mm – top heartwood to 1.142 ± 0.144 mm –base heartwood) which were all less than 1.6mm (1600μm). Runkel ratio was highest in top heartwood (0.26 ± 0.08); Flexibility Coefficient was highest in bottom sapwood (0.83 ± 0.05); and Slenderness Ratio was highest in bottom sapwood (49.18 ± 10.42).The derived fibre values were all within acceptable standard ranges for wood to be used for paper production: runkel ratio <1.0, Coefficient of Flexibility >75%, and slenderness ratio >33 that the 9-year old Cedrelaodorata hardwood in Ghana is a potential species to be used to produce pulp and paper of desired qualities, especially when it is mixed with other long fibre wood species. Thus, the 9-year fast grown Cedrela wood species is recommended for consideration among other known species for paper manufacturing in Ghana and elsewhere.

KEYWORDS: Ghana Paper; Wood fibres; Wood maceration; Cedrelaodorata; Runkel ratio

INTRODUCTION

Wood products especially fibre is reported to be one major product recognized in the socio-economic development in forest-based industries across the world on account of their applications in the pulp and paper industries [1]. This recognition is also emphasized by the important role papers play in the lives of humanbeings in the areas of human and environmental sanitation, communication and secretary-ship, mother care, health care etc. However, in recent times, inadequate fibre has been identified as one of the major challenges facing the pulp and paper industries [2]. Though paperis made from wood, it is not all wood species that have the fibres which conform to the desired qualities to be accepted for pulp and paper production.

For a wood species to be classified as a material for pulp and paper, its growth rate should be rapid for economical plantation management, the fibre it produces should be longer than average fibre length, the runkel ratio of the fibres should be less than 1, it should have low basic density, low ash content and low chemical extractives [3]. Thus, it is said that the quality of pulp and paper products is contingent on the morphology of the fibres and the chemical composition of the wood species [4]. Additional qualities of importance for considerations are that the species should have straight boles which aid debarking, and high fibre to non-fibrouis tissue ratio [5]. Thus, it is always important that more and more woodspecies are assessed in terms of the qualities expected of a potential pulp wood in order to recommend such species to augment the supply of fibre for the pulp and paper industry.

For some years now, Cedrelaodorata species, a member of the family Meliaceae has been planted in plantation forests in most regions of Ghana [6]. However, studies on the morphology (i.e., the anatomical cells characteristics) of the species in Ghana, especially in relation to vertical and horizontal variations and directed towards evaluation for paper production are either limited or unavailable. It is in this light that our present study focused on the variations in some anatomical characteristics of a 9-year C. odorata, at different vertical (bottom to top) and horizontal (sapwood to Heartwood) positions to as certain the species’ suitability for pulp and paper production.

EXPERIMENTAL PROCEDURE

Sampling site and Sampling

A total of five 9-year old Cedrelaodorata trees were felled, extracted from Tano-Off in reserve, and processed. This reserve is the largest among four in the Atwima Mponua District of Ghana, and it has the following descriptions (Table 1).

Table 1: Description of site where samples of 9-yr. Cedrelaodorata trees were extracted.

|

Vegetation |

Temperature |

Average Humidity |

Average Precipitation |

Geology |

|

Semi-deciduous with diverse flora and fauna of different species (MOFA, 2020) |

From 22.0°C to 31.1°C and averaging 27°C(MOFA, 2020; Forestry Commission, 2007) |

Monthly = 80% |

1700mm to 1850mm (March to May); 1000 – 1250 (August to November) though erratic and unpredictable (MOFA, 2020) |

Elongated mountainous range (including AyaBepo -Tributaries for Tano and offin rivers) with numerous steep slopes. Elevation is between 200m and 740m above sea level (MOFA, 2020; Birdlige International, 2011) |

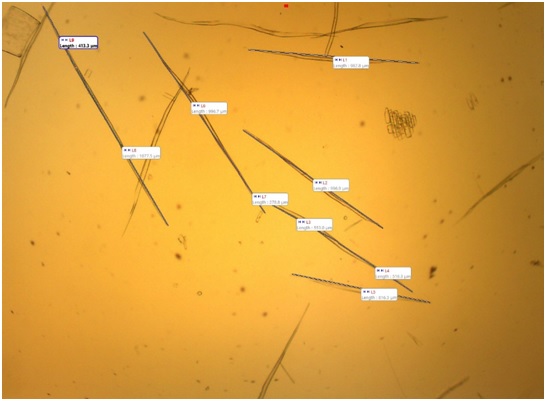

The felled and extracted trees were conveyed in boules and processed to boards of varied dimensions and in accordance with their tree positions (Bottom sapwood, Bottom heart wood, Top sapwood, and Top heart wood). These boules were air-dried to 14±2% MC and finally prepared to dimensions of 2cm square. For each of the 5 C. odorata trees eight samples were extracted (i.e., 2 top sapwood + 2 top heart wood + 2 bottom sap wood+ 2 bottom heart wood) and made a total of Forty. Matchstick sizes of each of the final samples were extracted for tissue macerationusing Franklin’s method where the samples were boiled for 5 minutes in concentrated Nitricacid (HNO3) to which a few crystals of potassium chlorate (KClO3) had been added. After teasing the macerates in glycerol, the fibre morphological measurements were taking (Figure 1) using Image J software (National Institute of Health, Bethesda, MD, USA).

Figure 1: Picture showing the fibres and how fibre lengths were measured. Scale bar = 100µm.

The parameters measured in micrometers (µm) included the fibre lengh (FL), fibre diameter (FD), fibre cell wall thickness (FWT) and fibre lumen diameter (FLD). Also, the derived characteristics associated with pulp and paper properties were also estimated as expressed in the following standard relations (equations 1-3):

Runkelratio (RR) = (2 x FWT)/FL ................................................. (1)

Flexibility coefficient (FC) = FLD/FD ........................................... (2)

Sllenderness Ration (SR) = FL/FD ............................................ (3)

Where FL is the fibre length (µm); FWT is the fibre wall thickness (µm); FD is the fibre diameter (µm); and FLD is the fiber lumen diameter (µm).

STATISTICAL ANALYSIS

Data collected were subjected to Student’s T-test (with SPSS 17.0) to ascertain whether or not there are significant differences between the obtained values (vertical and horizontal samples).

RESULTS AND DISCUSSIONS

Variations in Fibre Morphological Characteristics

At 5% significance level, indicate vertical (bottom to top) variations of fibre morphological characteristics were more significant (generally P<0.01) compared to horizontal (sapwood to heartwood) which appears dependent on cell type with irregular trend (Table 2).

Table 2: Descriptive Statistics and T-Test of Variations in Fibre morphological characteristics of 9 yr. C. odorata. Note: ***= P<0.01; **=P<0.05; *=P<0.1 and ns = P>0.1). SW = Sap wood, HW = Heart wood.

|

Fibre Morphological Features |

9 yrs Tree |

T-Value |

P-Value |

||

|

Bottom (SD) |

Top (SD) |

||||

|

Fibre length (μm) |

SW |

1138.54 (139.43) |

1084.30 (189.66) |

7.209 |

.000 |

|

HW |

1142.24 (144.52) |

822.29 (142.32) |

6.278 |

.000 |

|

|

T-Value |

-0.130 ns |

7.813 *** |

|||

|

Fibre diameter (μm) |

SW |

23.85(4.31) |

27.31 (5.78) |

-5.412 |

.000 |

|

HW |

24.83 (4.34) |

21.53 (2.96) |

-2.736 |

.007 |

|

|

T-Value |

-1.135 ns |

6.288 *** |

|||

|

Fibre lumen diameter (μm) |

SW |

19.85 (4.37) |

22.25 (5.61) |

-3.728 |

.000 |

|

HW |

19.97 (4.04) |

21.53 (2.96) |

-2.154 |

.034 |

|

|

T-Value |

-0.140 ns |

5.434 *** |

|||

|

Double fibre wallthickness (μm) |

SW |

4.00 (0.94) |

5.06 (1.32) |

4.030 |

.000 |

|

HW |

4.86 (1.50) |

4.15 (1.05) |

7.619 |

.000 |

|

|

T-Value |

-3.459 *** |

3.853 *** |

|||

The results show that whereas almost all fiber dimensions exhibited increases from sapwood to heartwood (horizontal variations) for bottom samples the opposite was the case for top samples. However, variations of the fiber dimensions from bottom to top (vertical variations) appear to have irregular pattern. These corroborate findings of Anoop, et al. [7] (2014) who observed similar trend. It is reported that, wood fibres of lengths above 1.6mm (1600.00 μm) are considered to be long fibres [8]. It could therefore be said from this present study that, Cedrelaodorata has short fibres with fibre length sranging from 0.822μm to 1.142μm – Table 2).

Long fibres have been found to produce paper with higher tear resistance [8,9]. Therefore, C. odorata papers may have low resistance to tearing, but the short fibres also tend to produce fine sheet structured paper [10]. Hence, though C. odoratamay not produce papers of high tensile strength but it will produce papers of fine structure. Findings also indicate that, some grades of printing and writing papers need a mixture of both short and long fibres together in order to yield good printability and opacity [2].

From the foregoing, at least, the C. odorata wood (short fibre wood) couldbe mixed with someother wood with long fibres so as to produce papers of a better improved qualities.

Variations in some Derived Values

Results indicated that, variations in both vertical and horizontal samples exhibited little significance (p<0.05) with horizontal samples at the top not showing any significant variations (p>0.1) in any derived value (Table 3).

Table 3: Descriptive Statistics and T-Test of Variations in some derived values of 9 yr. Cedrelaodorata (L.) fibres. Note: ***= P<0.01; **=P<0.05; *=P<0.1 and ns = P>0.1).

|

Parameter |

9- years old C. odorata |

T-Value |

Sig. |

||

|

Bottom |

Top |

||||

|

Runkel ratio (RR) |

Sapwood |

0.21 (0.07) |

0.24 (0.10) |

-0.894 |

0.421 |

|

Heartwood |

0.25 (0.09) |

0.26 (0.08) |

-0.113 |

0.518 |

|

|

T-Value |

0.064 ** |

- 0.106 ns |

|||

|

Flexibility coefficient (FC) |

Sapwood |

0.83 (0.05) |

0.81 (0.06) |

0.833 |

0.317 |

|

Heartwood |

0.80 (0.06) |

0.79 (0.05) |

0.321 |

0.430 |

|

|

T-Value |

0.148 ** |

0.238 ns |

|||

|

Slenderness ratio (SR) |

Sapwood |

49.18 (10.42) |

41.69 (12.83) |

2.009 |

0.003 |

|

Heartwood |

47.19 (9.57) |

38.98 (9.90) |

4.398 |

0.002 |

|

|

T-Value |

0.994 ns |

1.181 ns |

|||

The current study found that; Runkel ratio (RR) ranged from 0.21 (Bottom sapwood) to 0.26 (Top Heartwood), Flexibility Coefficient ranged from 0.79 (Bottom Heartwood) to 0.83 (Bottom Sapwood), whereas Slenderness Ratio (SR) ranged from 38.98 (Top Heartwood) to 49.18 (Bottom Sapwood).

Generally, according to the standards, RR shouldbe <1 and is considered most suitable for producing paper with desirable qualities. Fibres that have FC ranging from 0.50 to 0.75+ are also considered to be highly elastic. Such are the desired qualities of wood species suitable for papermaking, especially paper of good tensile and bursting strengths [1,11]. SR should be >33 to be able to produce paper with acceptable qualities [12,13]. Hence, the SR range of 38 -49 for C. odorata (Table 3) is also a favourable indicator that the 9-yrs tree fibres are better materials to produce paper of good quality.

CONCLUSIONS AND RECOMMENDATIONS

From the foregoing analysis and discussions, we conclude and recommend that 9-year C. odorata wood species in Ghana is a potentially good material to produce paper of desired qualities. There appears to be varied consistencies in vertical (from bottom to top) and horizontal (from sapwood to heartwood) in fibre morphological differences in the 9-year old Cedrela wood. We however recommend further studies into the chemical consumption during cooking and other properties of the species for better informed decision on the 9-yr C. odorata, in terms of its use for commercial paper production in Ghana and elsewhere.

ACKNOWLEDGEMENT

We render our appreciation to FABI Timbers Ltd in Ghana and all its staff that helped us in the processing of our samples. We also appreciate the help provided to us by the staff of the Anatomy Laboratory of the Forestry Research Institute of Ghana (FORIG) at Fumesua, Kumasi, especially Ante Esi and Mr. Govina.

REFERENCES

- Ogunjobi KM, Adetogun AC, Shofidiya SA. (2014). Investigation of Pulping Potentials of Waste from Conversion of Anogeissusleiocarpus. IOSR Journal of Polymer and Textile Engineering (IOSR-JPTE). 1(2):26-30.

- Sadiku NA, Abdukareem KA. (2019). Fibre morphological variations of some Nigerian guinea savannah timber species. Maderas Ciencia y Tecnologia. 21(2):239-248.

- Ogunkunle ATJ, Oladele FA (2008). Structural Dimensions and Paper Making Potential of the Wood in Some Nigerian Species of Ficus L. (Moraceae). Advances in Natural and Applied Sciences. 2(3):103-111.

- Cao S, Ma X, Lin L, Huang F, Huang L, Chen L. (2014). Morphological and Chemical characterization of Green bamboo {Dendrocalamopsisoldhami (Munro) Keng F.} for dissolving pulp production. BioResources. 9(3):4528-4539.

- Evans J. (1992). Plantation Forestry in the Tropics, 2nd ed., Claredon Press. Oxford.

- MOFA- Ministry of Food and Agriculture, (2020). Atwima Mponua District – Physical and Natural Environment. https://mofa.gov.gh/site/sports/district-directorates/ashanti-region/153-atwima-mponua. (Accessed, 16th August, 2020).

- Anoop EV, Ajayghosh V, Nijil JM, Jijeesh CM. (2014). Evaluation of pulp wood quality of selected tropical pines raised in the high ranges of Idukki District, Kerala. Journal of Tropical Agriculture. 52(1):59-66.

- Ajuziogu GC, Ojua EO, Aina DO. (2019). Comparative paper-makingpotentials of three species from the verbenaceae and lamiaceae. AsianJournal of Research in Botany. 2(4):1-5.

- Oluwader AO, Ashimiyu OS. (2007). Wood properties and selection for rotation length in caribean pine (Pinuscaribea Morelet) grown in Afaka, Nigeria. American Eurosian Journal of Agricultural and Environmental Science. 2(4):359-363.

- Shakhes J, Zeinaly F, MarandiMAB, Saghafi T. (2011). The effects of processing variable on the soda and soda-AQ pulping of Kenafbast fiber.BioResources. 6(4):4626-4639.

- Akgul M, Tozluoglu A. (2009). Some chemical and morphological properties ofjuvenile woods from beech (Fagusorientalis L.) and pine (Pinusnigra A.)Plantations. Trends in Applied Sciences Research. 4(2):116-125.

- Ona T, Sonoda T, Ito K, Shibata M, Tamai Y, et al. (2001). Investigation of relationships between cell and pulp properties in Eucalyptus by examination of within-tree property variations. Wood Science and Technology. 35(3):229-243. DOI:10.1007/s002260100090.

- Xu F, Zhong XC, Sun RC,Lu Q. (2006). Anatomy, ultrastructure and lignin distribution in cell wall of Caragana Korshinskii. Industrial Crops and Products. 24(2):186-193. Doi: 10.1016/j.indcrop.2006.04.002.

Copyright: Dadzie PK, et al. @ (2021). This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Citation: Dadzie PK, Amoah M, Inkum PB, Boampong E, Ansah Jr. VO. (2021). Vertical and Horizontal Cell Structural Appraisal of a 9-Year Cedrelaodorata L. (Miliaceae) for Pulp and Paper Making. Material Sci. 3(1):07.

Abstract

Abstract  PDF

PDF