Past Issues

Lightweight, Cost-Effective, and Environmentally Friendly Materials for a Mountain Bicycle Frame during High-Impact Riding: A Comparative Analysis of Traditional Aluminum, Aluminum 6013, and a BioMid Fiber™ Composite

Rishi Bansal1*, Basma Altaf2

1Del Norte High School, 16601 Nighthawk Ln, San Diego, CA 92127, USA

2Stanford University, USA

*Corresponding Author: Rishi Bansal, Del Norte High School, 16601 Nighthawk Ln, San Diego, CA 92127, USA; Tel: +1-858-776-2311; Email: [email protected]

Received Date: November 22, 2023

Publication Date: December 4, 2023

Citation: Bansal R, et al. (2023). Lightweight, Cost-Effective, and Environmentally Friendly Materials for a Mountain Bicycle Frame during High-Impact Riding: A Comparative Analysis of Traditional Aluminum, Aluminum 6013, and a BioMid Fiber™ Composite. Material Science. 5(2):22.

Copyright: Bansal R, et al. © (2023).

ABSTRACT

This literature review paper examines and compares three materials for a mountain bicycle frame: traditional aluminum, aluminum 6013, and a BioMid Fiber™ composite. Aluminum 6013 and the BioMid Fiber™ composite are alternatives to the aluminum alloys traditionally used in mountain bicycle frames: aluminum 6013 and aluminum 7005. These three materials were compared based on their strength, weight, cost, and environmental sustainability. Causes of failure were examined and design modifications were also considered. This work concluded that out of the four factors taken into account, aluminum 6013 and a hybrid of the BioMid Fiber™ composite with aluminum were favorable in two out of the four categories, whereas traditional aluminum was only favorable in one of these categories.

Keywords: Mountain biking; Materials engineering; Environmentally friendly materials; Mountain bicycle frame and design; Alternative materials for mountain biking; Aluminum alternatives

INTRODUCTION

Off-road cycling, better known as mountain biking, is a sport that branched off from typical road cycling in the early 1970s [1]. Whether it is for recreational purposes or for racing, mountain biking involves uneven terrain, which causes increased stress on the frame as compared to traditional road biking [1,2]. In addition to the terrain, forces created by the rider also contribute to stress on the frame [2,3]. Increased stress can lead to the fracturing or deformation of the frame [4,5], potentially injuring the rider. Frame strength, therefore, is a crucial factor when determining the material and design for the optimal bike frame. In addition to frame strength, there are several other factors that need to be considered for the optimal mountain bike frame.

Weight reduction is another key aspect to optimizing a mountain bike frame, as it requires more energy to ride a heavier bike than a lighter bike [6]. This task is often difficult, as frame strength must be maintained while reducing weight [2,3]. Bicycles are usually made of aluminum, steel, titanium, or carbon fiber. Despite being the lightest of these materials, aluminum is also the weakest [4]. There must be a balance between the strength and lightness of a mountain bike frame.

Cost effectiveness is another important factor to consider. While titanium is less dense than steel and much stronger than aluminum, it is much more expensive, making it impractical for the average cyclist. Grade 9 titanium, for example, is over 23 times more expensive than 6061-T6 aluminum, the most common material used for bicycles [4]. Similarly, bamboo bicycles are more environmentally friendly than metal bicycles. However, they are a small market in the bicycle industry due to their high costs [7].

In addition to these three factors, environmental sustainability must be considered. The United Nations defines this as “meeting the needs of the present without compromising the ability of future generations to meet their own needs” [8]. Mining metals, unfortunately, greatly disturbs the environment due to the emission of greenhouse gasses and the destruction of the landscape [9]. As bicycles are commonly made of metals, they indirectly affect the environment in a negative way. It is important to ensure that the manufacturing of bicycles is as safe for the environment as possible.

This literature review paper explores and compares three different materials for a mountain bike frame: traditional aluminum, aluminum 6013 [4], and a BioMid Fiber™ composite, specifically a hybrid between a cellulose-based fiber-reinforced composite and aluminum [2].

METHODS

This literature review is based on research articles published in the field of mountain biking. To ensure credibility, the majority of the literature was found using Google Scholar. Literature was obtained from approximately the last ten years. As the mountain biking industry does not evolve extremely quickly, it was decided that it was not necessary to limit the research to within the last five years. For the few articles found without using Google Scholar, care was taken to ensure the quality of the sources found.

After the literature regarding the topic of optimizing mountain bikes was found, careful notes were taken to ensure the relevance and quality of each research paper. Only the most relevant and well-written research papers were chosen for this literature review. Relevance was determined based on if the research was conducted specifically on mountain bikes and if it involved optimizing the frame. Quality was determined based on the thoroughness and clarity of the purpose of the research. This careful selection was done to ensure the quality of this literature review.

MATERIALS FOR MOUNTAIN BICYCLE FRAME

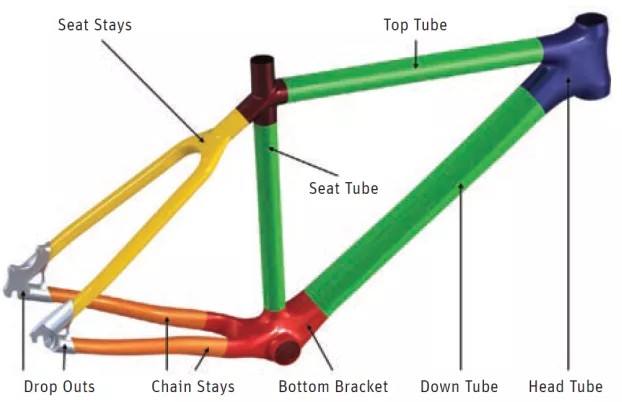

Most bicycles are made of a traditional diamond frame (Figure 1) which is made up of two triangles, separated by the seat tube. The seat tube extends upwards and attaches to the saddle, allowing the rider to sit. It must be noted that this model represents a rigid bicycle for simplicity. Rigid bicycles do not have a suspension system.

Figure 1: The Frame Components of a Rigid Bicycle. Figure taken from [10]

Generally, when determining the strength of a bicycle frame, fatigue testing must be conducted. This can be done by using a testing rig to apply a load in cycles to the bicycle. This can also be done with a model using finite element analysis (FEA) [4]. Specific fatigue testing for each material is discussed in the following sections.

Traditional Aluminum

Bicycle frames are typically made of aluminum. The two most common aluminum alloys used in the bicycle industry are aluminum 6061 and aluminum 7005 (Table 1) [4]. Aluminum 7005 is the stronger alloy between the two due to the greater percentage of zinc [4,5,11]. Aluminum 7005, however, is more costly and has a greater density than aluminum 6061 [5]. However, when compared to other potential metals for bicycle frames, aluminum is extremely cost effective [4].

Table 1: A Comparison of the Mechanical Properties of Aluminum 6061 and Aluminum 7005. Table taken from [4].

|

Materials |

Modules of Elasticity (GPa) |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Fatigue Strength at 50,000 Cycles (MPa) |

Density (kg/m3) |

Cost (USD per Kg) |

|

Aluminum-6061-T6 |

72 |

193-290 |

241-320 |

75 |

2700 |

$2.42 |

|

Aluminum-7005-T6 |

72 |

290 |

350 |

̴75 |

2780 |

$2.87 |

Causes of Failure

Fatigue in bicycle frames is caused by stress from static and dynamic loads [3]. The static load is when the bicycle is driving at constant speed, loaded by its own weight and the weight of the rider [3]. The dynamic load takes external forces into account, such as acceleration, braking, the shifting weight of the rider, and the roughness of the terrain [3]. Frame twisting is another form of stress on the frame [2,3]. This can be caused by riding out of the saddle [3]. Out of saddle pedaling causes asymmetrical loading on the frame, which in turn, causes greater stress on the bicycle frame [3]. Frame twisting can also be caused by cornering through curves [2]. In addition to these causes of stress, there are other more specific causes of stress, as discussed in the following sections.

Jumps

Landing jumps creates stress in the frame, caused by the displacement of the rear wheel [2].

This is also determined by the stiffness of both the front and rear shock absorbers [2]. Researchers analyzed the stresses from jumping, and determined that it most affected the linkage part that joins the main frame with the moving parts of the rear suspension [3].

Creation of Frames & Welding of Tubes

Another cause of fatigue in a bicycle frame is from the process of creating the frame itself. Several researchers determined that cracks in the frame originate from the weld joints in the head tube and bottom bracket [3,4]. The first step in creating a bicycle frame is hydroforming [4]. This involves placing the tube into a steel mold. Water is then forced under high pressure through the tube. The tube resultantly conforms to the shape of the steel mold. Following hydroforming, the tubes must be miter cut. Mitering is the process of cutting the end of the tube at an angle to allow it to sit perfectly flush with another tube as they are joined together. Once miter cut, tubes are joined together by welding [4].

The most common form of welding is tungsten inert gas (TIG) welding. TIG welding is a common choice for manufacturers due to its affordability and high-quality finish. TIG welding, however, has its drawbacks. Due to the high temperature of this process, a small area of the metal exhibits a change in properties. This area, called the heat-affected zone (HAZ), suffers from weakened mechanical properties, such as a decrease in hardness and a loss in ultimate tensile strength of up to 34% [4].

To compensate for the loss of mechanical properties, the frames undergo a heat treatment process. Aluminum 6061 frames usually undergo a T6 heat treatment process, involving solution heat treatment, quenching, and artificial age hardening [4]. The T6 heat treatment process allows the frame to recover 30% of its original strength [4].

There are alternatives to TIG welding. Friction Stir Welding (FSW), is a process that uses downward pressure and a lower temperature [4]. This does create a thermo-mechanically affected zone (TMAZ) and a HAZ, however FSW is still better than TIG at retaining the original properties of the frame [4,12]. According to a study published in the International Journal of Engineering Research & Technology (IJERT), FSW saves energy due to a lower energy requirement than TIG welding, is cost effective, and creates weld joints that are stronger than when TIG welding is used [12]. Although a suitable, and possibly more desirable alternative to TIG welding, FSW welding is unfortunately not used in the bicycle industry, since its application in this industry has not been explored yet [4].

Several studies have modified aluminum frames to make them stronger. These modifications change the design of the aluminum frame, rather than the material.

Researchers F. Dwyer et al. (2012) from the Worcester Polytechnic Institute (WPI) determined that the fatigue from weld joining the head tube can be reduced by increasing the weld length by 50% [4]. They also increased the curvature of the down tube near this weld. These modifications were tested with finite element analysis (FEA) and indeed proved to decrease the stress on the head tube weld. These geometry modifications decreased the stress by creating a larger area for the load to be distributed upon. Dwyer et al. also determined that the weld joint in the bottom bracket was a location that exhibited fatigue from stress, so they increased the thickness of the down tube near the bottom bracket [4]. They then tested both geometry modifications using FEA and found that combining these modifications increases the cycles to failure by 22%. While these modifications do increase the strength of the bicycle, it must be noted that these geometry modifications also increase the weight of the bicycle frame.

Researchers V. Bulej et al. (2022) determined that landing jumps causes stress to the linkage component of the rear suspension, so they redesigned this component to increase its strength. They redesigned this component by removing two ribs and using a square profile with a pin housing system. Using FEA, they determined that the maximum stress the new design suffered was 2.5 times lower than the original design. In addition to reducing stress from landing jumps, the redesign also reduces stress when pedaling out of saddle.

Environmental Sustainability of Aluminum

Mining Aluminum

As aluminum is a metal, it must be first obtained by mining. Mining, unfortunately, has devastating consequences for the Earth and its environment [9]. The heavy machines required for mining have a carbon output that disturbs the environment [9]. Mining requires large plots of land which leads to deforestation [13] and soil erosion [9]. Mining is heavily dependent on water, which is required for extraction, processing, and the disposal of waste [9]. This water, however, can contaminate natural water sources if not treated properly [9,13]. Aluminum comes from an ore called bauxite. 2.9 metric tons of bauxite creates 1 metric ton of aluminum [14]. Bauxite produces toxic residues and radioactive substances that are harmful to the environment [14].

Processing Aluminum

After mining, the aluminum must be extracted and refined. This involves an energy intensive smelting process, sourced from fossil fuels [14]. This can lead to problems like eutrophication, acidification, smog, global warming, and ozone depletion [14]. The aluminum smelting process also leads to toxins in the environment that can affect humans; the toxins are both carcinogenic and non-carcinogenic [14].

Recycling Aluminum

Aluminum is a metal that is commonly recycled. Aluminum frames often have a lifespan of 5- 10 years due to their brittleness [15]. For this reason, the question of whether bicycle frames can be recycled or not may arise. There is not much research conducted on the recycling of aluminum bicycles. However, a research paper by Y.-J. Chang et al. stated that 60% of the aluminum used for bicycles in Germany is recycled [16]. Another group of researchers, A. Akhyar et al. (2021), were able to successfully create a cast aluminum bicycle out of recycled materials [15]. The benefit to creating a bicycle from a mold is that costs may decrease due to the high costs of welding equipment [15]. However, other than this, not much other research could be found on the recycling of aluminum to make bicycles. While sustaining bicycle production through recycling may be a possibility in the future, based on the limited research, it appears as if mining will continue to be the dominant source of aluminum for bicycles.

Aluminum 6013

Aluminum 6013 is an aerospace alloy that is a suitable alternative to traditional aluminum alloys used in bicycle frames [4]. This alloy has the same cost, yet a 32% higher yield strength and ultimate tensile strength and nearly a 50% higher resistance to fatigue failure than aluminum 6061 (Table 2) [4]. Aluminum 6013 also has a similar modulus of elasticity and density, so the riding experience on this bike would likely feel similar to a typical aluminum 6061 bike [4]. These desirable properties result from the decreased iron content and increased copper content in the aluminum 6013 alloy [4].

Aluminum 6013 is not prevalent in the bicycle industry due to its limited availability [4].

There is, however, one bicycle manufacturer that is pioneering the use of aluminum 6013 in some of its bicycles. A German bicycle company, LAST Bikes, has started creating some of their bicycle frames out of aluminum 6013 [17].

Table 2: A Comparison of the Mechanical Properties of Aluminum 6061 and Aluminum 6013. Table taken from [4]

|

Materials |

Modules of Elasticity (GPa) |

Yield Strength (MPa) |

Ultimate Tensile Strength (MPa) |

Fatigue Strength at 50,000 Cycles |

Density (kg/m3) |

Cost (USD per Kg) |

|

6061-T6 |

72 |

250 |

280 |

95 |

2700 |

$2.42 |

|

6013-T6 |

70 |

330 |

370 |

140 |

2710 |

$2.42 |

Design Modifications to Aluminum 6013 Frames

Researchers Dwyer et al. (2012) who tested the frame geometry modifications for traditional aluminum bicycles as seen in section 3.1.2 also applied this to a model using aluminum 6013, which predicted the fatigue life using FEA [4]. The model predicted 3,500,000 cycles to failure, which was nearly six times stronger than aluminum 6061 with this geometry and over seven times stronger than aluminum 6061 without these design modifications [4].

Environmental Sustainability of Aluminum 6013

Since aluminum 6013 is just another alloy of aluminum, the environmental implications of this alloy are quite similar to aluminum 6013 and aluminum 7005. It is harmful for human beings and the environment due to mining, and there is the potential to increase sustainability through recycling. Another alternative is natural materials, as discussed in the following section.

BioMid Fiber™ Composite

Natural fiber composite materials are potentially desirable alternatives to metals for bicycle frames due to their biodegradability [18]. One such example is a BioMid Fiber™ composite. This material is extremely lightweight, environmentally friendly, and potentially recyclable [2]. The density of this composite is about 55% less than aluminum 6061 [2][4]. Information on the cost of this material could not be found. This material has not yet been used in the bicycle industry.

Researchers M. Collotta et al. (2018) from Università degli Studi di Brescia created a new concept for a downhill mountain bike that used a hybrid of a BioMid Fiber™-reinforced composite material with aluminum [2]. These researchers also designed a racing boat out of natural fiber-reinforced composite materials [19]. They started by attempting to create a bicycle frame out of a BioMid Fiber™-reinforced composite alone [2]. This composite material combines BioMid Fiber™ and Super Sap® CLR epoxy to create a strong, lightweight, and environmentally friendly material [2]. Unfortunately, after a numerical analysis, they found that this composite alone was not strong enough to be suitable for a mountain bike frame [2].

Design Modifications to the BioMid Fiber™ Composite Material

To bypass this issue, they integrated the composite with aluminum elements and increased the size of the frame tubes, both of which strengthened the frame [2]. More specifically, they placed an aluminum plate in between the top tube and the down tube [2]. This allowed for a smoother transfer of forces between tubes to avoid buckling [2]. They also increased the diameter and thickness of the tubes made of the BioMid Fiber™ composite [2]. These modifications brought the frame strength up to about the same as a traditional aluminum frame [2]. This hybrid frame, however, was much lighter [2]. The tubular elements, fully using the BioMid Fiber™ composite, had a weight reduction of about 25% from traditional aluminum [2]. It must be noted that despite the density of the composite being approximately 55% less than that of aluminum 6061, the size of the composite material tubes were increased, resulting in the weight being approximately 25% less than that of aluminum 6061. The new frame was also about half as stiff as a traditional aluminum frame [2]. This stiffness depends on the rider’s preferences, and may be increased by adding aluminum plates [2].

Environmental Sustainability of the BioMid Fiber™ Composite Material

Ninety-three percent of harvested trees are used for the lumber industry. The remaining 7% is considered waste [20]. This remaining 7% is used as a source of cellulose to create BioMid Fiber™ [20]. The BioMid Fiber™ production process is zero-waste and uses only water, cellulose, a reusable solvent, and electricity [20]. The electricity is completely wind generated. BioMid Fiber™ by itself, therefore, is extremely environmentally sustainable [20].

Super Sap® CLR epoxy is a renewable sourced, environmentally friendly epoxy [2]. Super Sap® is made with minimal harmful byproducts and reduced greenhouse gas emissions [21].

Entropy Resins®, the creator of Super Sap®, aims to create epoxies that have a low impact on the environment [4].

However, since the BioMid Fiber™ composite was used in combination with aluminum to ensure suitable frame strength, the hybrid material is not as environmentally sustainable as the BioMid Fiber™ composite alone. It is, though, a big improvement from a traditional aluminum frame since it uses a significantly smaller amount of aluminum.

DISCUSSION

After conducting a literature review on three materials for a mountain bicycle frame, it can be seen that each of the three materials have desirable traits based on strength, weight, cost, and environmental sustainability, as summarized in table 3. In addition to these four factors, it was noted that there are several others to consider for optimum bicycle frame design. These factors include the stiffness of the frame, the potential to be mass produced in the bicycle industry, and recyclability, although this goes hand in hand with environmental sustainability. For example, aluminum 6013 has a greater potential to be mass produced in the bicycle industry than the BioMid Fiber™ aluminum hybrid due to its similarities to traditional aluminum and the start of its usage in bicycles for everyday consumers by Last Bikes.

Furthermore, it was also considered that certain material and design modifications could be combined to create an even greater optimized mountain bike frame. For example, the aluminum frame design modifications created by Dwyer et al. could be applied to the BioMid Fiber™ composite frame. The aluminum plates used in the BioMid Fiber™ aluminum hybrid frame could be made of aluminum 6013 instead of aluminum 6061. FSW welding could be used on aluminum 6013 frames. There are so many ways to integrate these frame optimizations together.

Additionally, these factors depend on the preferences of the rider themself. Some riders may prefer to spend more money for a stronger frame. Other riders may be willing to sacrifice strength for environmental sustainability. A third group of riders may prefer stiffer bicycles over others. In the end, these factors all truly depend on the preferences of the rider. For these reasons, a single material cannot be chosen as the “best” option.

Table 3: A Comparison of Strength, Weight, Cost, and Environmental Sustainability Between Traditional Aluminum, Aluminum 6013, and a BioMid Fiber™-Reinforced Composite & Aluminum Hybrid for a Mountain Bicycle Frame

|

Material |

Strength |

Weight |

Cost |

Environmental Sustainability |

|

|

Traditional Aluminum |

Aluminum 7005 |

High |

High |

High |

Medium |

|

Aluminum 6061 |

Medium |

Medium |

Low |

Medium |

|

|

Aluminum 6013 |

High |

Medium |

Low |

Medium |

|

|

BioMid Fiber™-Reinforced Composite & Aluminum Hybrid |

Medium |

Low |

Unknown |

High |

|

Cell highlights indicate favorable characteristic

Limitations & Future Work

It is important to note that this paper does not consider all possible designs and materials for a mountain bicycle frame. Many other materials not discussed exist, such as carbon fiber, bamboo, and wrought magnesium alloys that may also be suitable alternatives to aluminum frames [7,22].

There was also limited research on the recyclability of aluminum in the bicycle industry, the application of BioMid Fiber™ composite in bicycles, and the application of aluminum 6013 in bicycles. As such, it is recommended that future work explores these practices and materials in the bicycle industry. It is also recommended that future research considers integrating the material and designing modifications together, as discussed earlier in the discussion section.

CONCLUSION

In conclusion, the advantages and disadvantages to traditional aluminum, aluminum 6013, and a BioMid Fiber™ composite as frame materials for a mountain bicycle frame were explored.

Factors considered were strength, weight, cost, and environmental sustainability. Design modifications to these materials were also taken into consideration. As of 2023, aluminum 6013 may be the most realistic material alternative to traditional aluminum, due to its high strength, low cost, and potential to be mass produced in the bicycle industry. However, despite aluminum 6013 being strong and cost effective, unless recycled, it is not environmentally sustainable. All in all, no single material can be chosen as the “best” option since in the end, these factors depend on the rider's own preferences.

REFERENCES

-

Cycling USA. (2020). What is mountain biking? USA Cycling. https://usacycling.org/article/what-is-mountain-biking

- Collotta M, Solazzi L, Pandini S, Tomasoni G. (2018). New design concept of a downhill mountain bike frame made of a natural composite material. Proceedings of the Institution of Mechanical Engineers, Part P: Journal of Sports Engineering and Technol. 232(1):50–56.

- Bulej V, Kuric I, Sága M, Vaško M, Ságová Z, Bartoš M, et al. (2022). Analysis of symmetrical/asymmetrical loading influence of the full-suspension downhill bicycle’s frame on the crack failure formation at a critical point during different driving scenarios and design improvement. Symmetry. 14(2):255.

- Dwyer F, Shaw A, Tombarelli R. (2012). Material and design optimization for an aluminum bike frame. Worcester Polytechnic Institute, Degree of Bachelor of Science Thesis, Travanj. http://web.wpi.edu/Pubs/E-project/Available/E-project-042612-124752/unrestricted/Material_and_D esign_Optimization_for_an_Aluminum_Bike_Frame.pdf

- Gupta R, Rao G. (2016). Analysis of mountain bike frame by FEM. IOSR J Mech Civil Engineering (IOSR-JMCE). 13(2):1–12.

- Lin B. (2019). Bike weight: How much better are lighter bikes? Does bike weight matter? The Pro’s Closet. https://www.theproscloset.com/blogs/news/the-weight-equation-how-important-is-a-light-bike

- Penava F, Jakovljevic S, Alar Z. (2016). Bamboo Bicycle - Past or Future? Interdisciplinary Description of Complex Systems. 14(1):70–79.

- Patterson N. (2022). What is Environmental Sustainability? Goals with Examples. Southern New Hampshire University. https://www.snhu.edu/about-us/newsroom/stem/what-is-environmental-sustainability

- Environmental risks of mining. (2016). Massachusetts Institute of Technology. https://web.mit.edu/12.000/www/m2016/finalwebsite/problems/mining.html

- Chase. (2017). Engineering.Com - how to design the lightest possible bike - and still sleep at night. Collier Aerospace. https://collieraerospace.com/2017/03/09/engineering-com-how-to-design-the-lightest-possible-bike-a nd-still-sleep-at-night/

- Bicycle aluminium alloys: 6061 and 7005. (2018). Aluminium Guide. https://aluminium-guide.com/en/velosipednaya-rama-alyuminievye-splavy-6061-i-7005/

- Singh P, Gandhi SK, Shergill H. (2012). Comparative study of friction stir and TIG welding for aluminium 6063-T6. Int J Engineering Res Technol (IJERT). 1:1–6.

- Gaikwad S. (2022). Environmental impact of aluminum production. ThePipingMart Blog. https://blog.thepipingmart.com/metals/environmental-impact-of-aluminum-production/

- Farjana SH, Huda N, Mahmud MAP. (2019). Impacts of aluminum production: A cradle to gate investigation using life-cycle assessment. Sci Total Envir. 663:958–970.

- Akhyar A, Nasution AI, Mulyagusdin A, Ibrahim M. (2021). Economic Impact Analysis Versus Investment Analysis: Cast-Bike Frame Manufacturing from Recycled Aluminum Alloy. Jurnal Teknik Mesin. 9(1):1–8.

- Chang YJ, Schau EM, Finkbeiner M. (2012). Application of life cycle sustainability assessment to the bamboo and aluminum bicycle in surveying social risks of developing countries. 2nd World Sustainability Forum, Web Conference:1–30.

- Benson C. (2017). Cook up more aluminum enduro with new Last Coal mountain bike. Bikerumor. https://bikerumor.com/cook-up-more-aluminum-enduro-with-new-last-coal-mountain-bike/

- Sundeep D, Varadaraj EK, Ephraim SD, Sastry CC, Krishna GA. (2022). Mechanical, morphological and thermal analysis of unidirectional fabricated sisal/flax hybrid natural fiber composites. Surface Topography: Metrology and Properties. 10(1):015028.

- Collotta M, Solazzi L, Pandini S, Donzella G. (2016). Design and realization a skiff racing boat hull made of natural fibers reinforced composite. Viii International Conference on “Times of Polymers and Composites”: Aerospace to Nanotechnol. 1736:020131.

- How is BioMid fiber made? (n.d.). BioMid Fiber. Retrieved August 8, 2023, from https://biomidfiber.com/how-is-biomid-fiber-made%3F

- Super sap. (2020). Entropy Resins. https://entropyresins.com/sustainability/super-sap/

- Deetz J. (2005). The use of wrought magnesium in bicycles. JOM J Minerals Metals Mater Society. 57(5):50–53

Abstract

Abstract  PDF

PDF